Which Type of Lathe Machine is Mostly Used?

When it comes to precision machining, lathe machines are indispensable tools. From crafting intricate parts to shaping raw materials, the right lathe machine can make all the difference. But with various types available, how do you determine which one is most widely used? In this blog, we’ll explore the different types of lathe machines, their applications, and why certain models are favored in the industry.

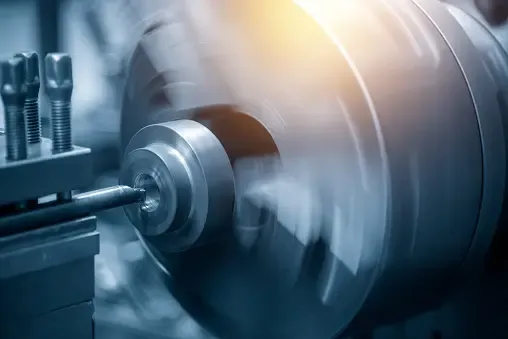

Understanding Lathe Machines

Lathe machines are versatile tools that rotate a workpiece to cut, sand, drill, or shape it. They come in various types, each designed to handle specific tasks. The core principle behind all lathes is the same: they rotate the material while a cutting tool removes excess material to achieve the desired shape.

The Most Common Types of Lathe Machines

Engine Lathes

Engine lathes are the most common type of lathe machine used in workshops today. They are known for their versatility and are capable of performing a wide range of operations, including turning, drilling, and threading. Engine lathes come in various sizes and configurations, making them suitable for both small-scale and large-scale projects. Their adaptability makes them the go-to choice for many machinists and hobbyists.

CNC Lathes

CNC (Computer Numerical Control) lathes represent the pinnacle of modern machining technology. These machines use computer controls to automate the cutting process, allowing for high precision and repeatability. CNC lathes are extensively used in manufacturing industries where consistent quality and complex shapes are required. They offer a significant advantage over manual lathes by reducing human error and increasing production efficiency.

Turret Lathes

Turret lathes are designed for high-volume production and are equipped with multiple cutting tools mounted on a turret. This setup allows for quick changes between different tools and operations, making turret lathes ideal for producing multiple parts in a short time. They are commonly used in industries where batch production and efficiency are crucial.

Bench Lathes

Bench lathes are smaller and more compact, making them suitable for use on a workbench or small workshop space. Despite their size, they can handle various tasks, including precision work on smaller parts. Bench lathes are popular among hobbyists and small-scale manufacturers who need a reliable tool for detailed work without the bulk of larger machines.

Factors Influencing the Choice of Lathe Machine

1. Project Requirements

The choice of lathe machine often depends on the specific requirements of the project. For high-precision tasks and complex shapes, CNC lathes are preferred. In contrast, for simpler and more straightforward machining tasks, engine lathes or bench lathes might be sufficient.

2. Production Volume

For high-volume production, turret lathes are typically the best choice due to their efficiency and speed. They can handle large quantities of parts with minimal setup time, making them ideal for mass production environments.

3. Space and Budget

The physical space available and the budget also play significant roles in selecting a lathe machine. CNC lathes and turret lathes generally require more space and a higher investment compared to smaller engine or bench lathes.

4. Skill Level

The operator’s skill level is another important consideration. CNC lathes, while highly efficient, require specialized knowledge to program and operate. On the other hand, engine lathes and bench lathes can be operated with basic training and are suitable for a wide range of skill levels.

Conclusion

In summary, the type of lathe machine most commonly used depends on various factors, including the specific needs of the project, production volume, available space, and the operator's skill level. Engine lathes are versatile and widely used for general machining tasks, while CNC lathes are preferred for high-precision and automated processes. Turret lathes excel in high-volume production, and bench lathes are ideal for smaller, detailed work. Understanding these factors can help you choose the right lathe machine for your needs.